While cranes lift up heavy pillars and hollow-core slabs at the Oodi worksite, also light manual tools are needed for working on the details. Special attention has been paid to welded joints. In March, Suomen Testauspalvelu Oy began inspections of the welded joints of the steel arches that support the entire library. For this task, they needed a small ultrasound device, magnetic particles and a hand-held electromagnetic yoke.

“We started the inspections from the south and north ends of the arches. When a welded joint is inspected, it is complete. We make sure that no welding mistakes have occurred and that the welded joint has not cracked during cool-down. Even though welding is carried out inside a weather guard tent, it is possible that hydrogen may develop in the joint, especially during rain or in humid air conditions. This may cause a delayed crack”, said managing director Tarmo Tuomela while checking the screen of the ultrasound device.

These tests must be done very carefully, as the welded joints to be inspected with the ultrasound device are only two or three millimetres thick. There are so many of them that, together, they make up the whole thickness of the arch’s casing, 120 millimetres.

“The ultrasound device transmits the sound at the steel, using a selected angle. If the joint is faultless, the sound moves through the steel without any problems. Any defects reflect the sound back. Hand-welded joints quite often have small defects that reflect the sound back, and then we need to review whether the joint can be approved or whether it needs to be opened and rewelded”, Tarmo Tuomela says, explaining the basic idea behind the method.

In addition to the ultrasound inspections, magnetic particle inspection will be performed on the joints. First, Tarmo Tuomela will spray white paint as a contrast colour onto the surface of the steel casing’s welded surface. When the paint is dry, he will grab the spray bottle and cover the surface with some black magnetic particle powder. The idea of this method is that the magnetic particles will gather on the possible defect when the yoke (pictured) with positive and negative magnetic poles is held above the substance.

Weather guard tents are a clear sign of where welding work is taking place on the arches. Each arch has seven welding sites, which means that there are total of 14 places were joints are made. The weather guard tents of the end casings are not shown in the picture. The arch load is still resting on the support grids, at this point.

As an installation site, the Central Library is a medium-sized worksite for Suomen Testauspalvelu. Previously, the company performed the steel structure inspections for Kamppi shopping centre, for example, and it is also in charge of the inspections of the engineering works on REDI shopping centre’s steel parts.

“We carried out the first inspections of the library’s steel structures back at the Normek engineering works in Oulu. Our special competence is physical dimensional inspection, i.e. the control measurements of various parts. They establish whether steel pillars, for example, have been made correctly and whether their holes are in the right places. Even a small difference would multiply during the installation, causing major problems for the heavy structures”, says Tarmo Tuomela.

Pillars in place on the north side

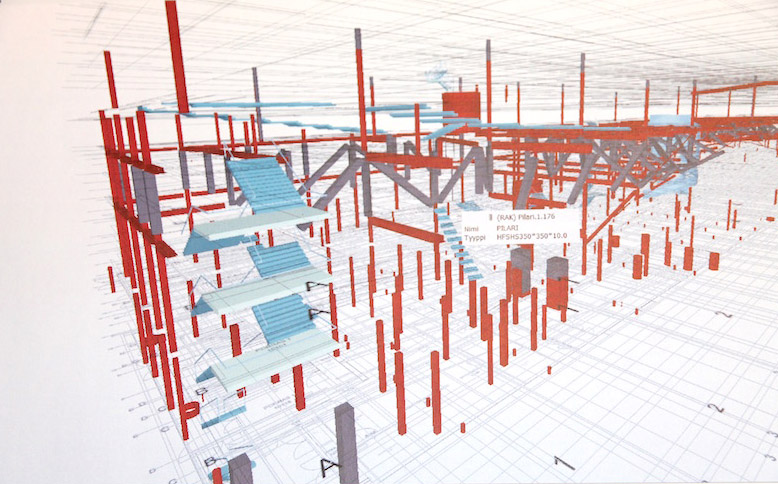

The library will be built from the north side towards the south. For the general public, one of the most interesting points on the north side is the cinema, first of its kind in the history of Finnish libraries. In this computer model, the cinema is shown in red, as are the first steel pillars of the frame behind it.

The north end of the building, the space between the stairwell shafts and cinema, will house both premises for building services and office spaces. Installation of stair elements has been started in shaft number one, on the left. In shaft number two, the cast-in-situ works of staircase landings are in progress. The ends of the steel arches that support the building are shown in blue in the image.

The shape of the cinema and its ascending floor can be clearly seen in the image. The area has been covered with the first hollow-core slabs that will become the floors and ceilings of different floors.

Erection of the frame will start with the steel pillars. The vertical pillars will be joined by horizontal beams, and, gradually, the frame will become an enormous grid structure.

The root of a steel pillar is being prepared for installation next to the cinema, in the future foyer. The frame is being built one pillar and one beam at a time, like a jigsaw puzzle in a gigantic scale.

The western side of the completed building will feature a long balcony with a beautiful view towards Kansalaistori and the Parliament House. The balcony will also be built on steel grids. The southernmost of them was installed in March.

Each jigsaw puzzle piece and every installation costs money. These costs are monitored and budgeted for by site engineer Ville Nevala. He is studying civil engineering and construction economy at Aalto University.

“My thesis is almost finished. For my bachelor’s degree, my thesis subject was foundation and rock engineering, and my current thesis is related to planning management and scheduling.”

Nevala thinks that the Oodi worksite has stayed well within budget and on schedule. Nearing the spring, keeping to the schedule for frame works has required hiring some more resources.